Over the past few months, the issue of gas pipelines and their restrictions due to cathodic protection has been identified and managed by BTS for a number of clients who were otherwise unaware of the implications cathodic protection can have for a development.

It’s not a term that comes up often in planning meetings, but cathodic protection (CP) can have a major impact on development feasibility, particularly when working near high-pressure gas pipelines, fuel lines, or other buried metallic infrastructure.

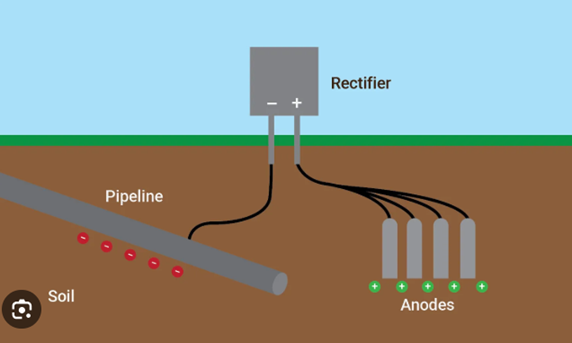

Cathodic protection is a corrosion control method. It is used by utility companies to prevent metal pipes from deteriorating underground. In simple terms, it involves applying an electric current to the pipeline to prevent it corroding, thereby extending its life and maintaining safety.

So why do developers need to be aware of this? Because CP systems create strict “interference zones.” Any nearby construction, from piling and steel reinforcement to drainage runs and building foundations, can disrupt the delicate electrical balance that keeps the pipeline protected. Any disturbance could trigger extensive technical assessments, redesigns, or even halts to construction until the necessary mitigation measures have been approved.

Therefore, we make sure our clients understand these constraints early on. Our team works with asset owners to assess CP risk, obtain clearances, and ensure compliance with HSE and network operator standards. By factoring in these technical details from the outset, developers can avoid costly redesigns and critical delays further down the line.

Cathodic protection may take place out of sight underground but it should never be out of mind. Its implications for a development are very real. Awareness and early engagement are the best protection you can give your project.